SMT Introduction

SMT設備

- 網印機:EKRA E5 , EKRA E4 ,EKRA X4 , Panasonic NM-EJP1A

- 錫膏檢查機:TRI TR7006 3D, TRI TR7007 SII

- 視覺辨識檢查 (AOI):TRI7530DT,TRI7530DT

- 點膠機:Panasonic NM-DC10

- 貼片高速機 (High Speed):Panasonic CM-602, Panasonic NPM

- 貼片泛用機 (Multiple):Panasonic NPM

- 氮氣回流焊爐 :Tamura TNP 40-578EM, Tamura TNP 40-577PM, Rehm

- X-ray 檢查機:GE-Phoenix X-Ray Inspector

- BGA 維修站:Ersa HR 600/2

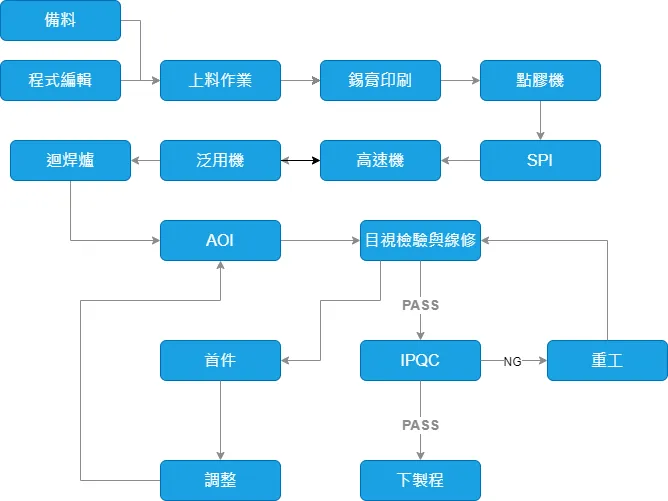

SMT Process

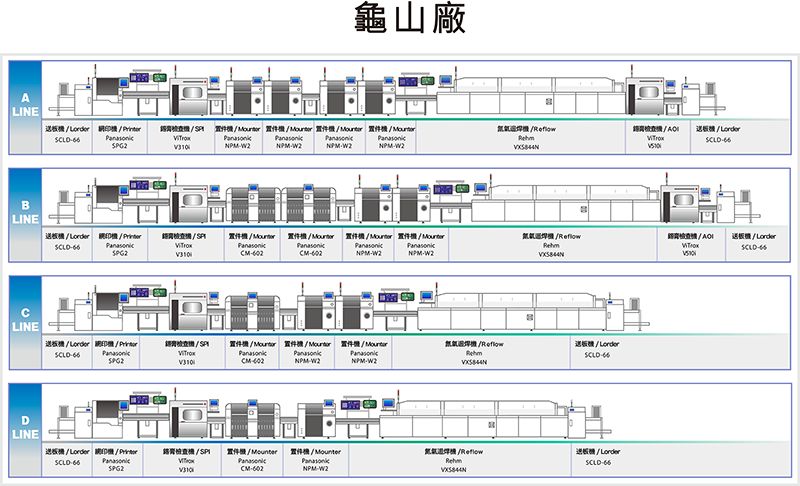

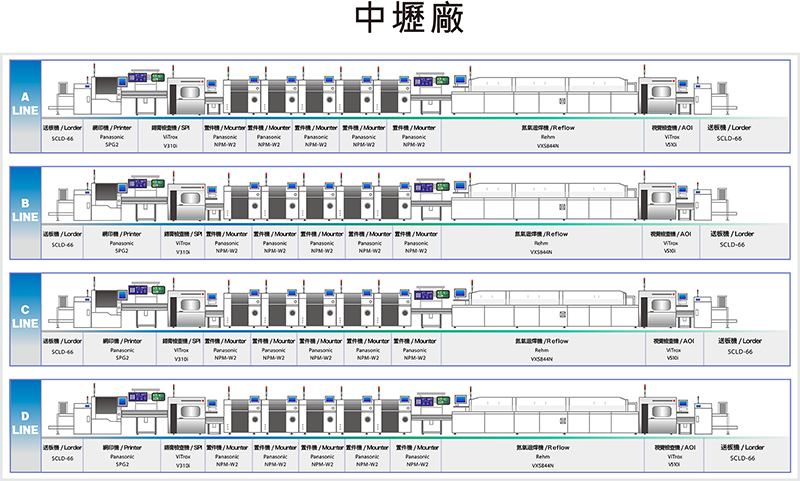

SMT Production Line

SMT Equipment Description

01_Solder Printer

Panasonic_SPG2

These solder stencil printers help precisely place solder paste where you want it on your printed circuit board without a mess or hassle.

- PCB Dimensions:L 50 × W 50 to L 510 × W 510

- PCB Exchange Time:14 sec including transfer

- Printing Accuracy:2Cp ±15.0 μm 6σ (±3σ)

02_Solder Paste Inspection

Vitrox_SPI_v310

Solder Paste Inspection, abbreviated as SPI, is a specialized process that evaluates/inspects solder paste deposit quality on PCBs.

It ensures the correct deposition of solder paste on the board without faults.

- Maximum PCB Size (L x W):510mmx510mm

- Maximum PCB Inspectable Area (L x W):

- PCB Transport Height:875mm-965mm

03_Mounter

Panasonic-CM602

Panasonic CM602-L high-speed module placement machine, CM602-L placement machine not only follows the original module of Panasonic CM402, but also adds 12 nozzle high-speed head and direct suction tray as needed.

- Placement Speed:100,000 cph (0.036 s/chip)

- PCB Dimensions:750 x 550 mm

04_Mounter

Panasonic NPM-W2

The multifunctional NPM-W2 is equipped with a 12-nozzle head and can place 38,500 components.

120 feeders can be mounted.

- Placement Speed:38,500cph (0.094 s/ chip)

- PCB Dimensions:750 x 550 mm

05_3D Automated Optical Inspection

Vitrox_3D AOI_v510i

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera autonomously scans the device under test for both catastrophic failure (e.g. missing component) and quality defects (e.g. fillet size or shape or component skew).

It is commonly used in the manufacturing process because it is a non-contact test method

The V510i Optimus 3D AOI system is a next generation solution for the SMT line, offering the powerful 3D inspection capabilities.

- Maximum PCB Size (L x W):490mmx510mm (19.2"x20")

06_N2 Reflow

Reflow_Rehm_VXS

A reflow oven is a machine used primarily for reflow soldering of surface mount electronic components to printed circuit boards (PCBs).

In commercial high-volume use, reflow ovens take the form of a long tunnel containing a conveyor belt along which PCBs travel.

For prototyping or hobbyist use PCBs can be placed in a small oven with a door.

Modular system concept

- Efficient heat transfer

- Stable process for lead-free applications

- Minimal downtime

- Integrated residue management

- User-friendly software tools for process monitoring

In the VisionX-Series the soldering process is performed on the basis of convection – that is, the transfer of heat via a flow of gases. Our systems are available in air or nitrogen versions. As an inert, protective gas, nitrogen is the ideal heat transfer medium and prevents disturbing oxidation during the soldering process. The modular system configuration of the VisionXS also offers a high level of flexibility for your production facility.