Conformal Coating Introduction

Conformal Coating Equipment

- Precision coating machine:PVA Delta 6, iCoat-5< / li>

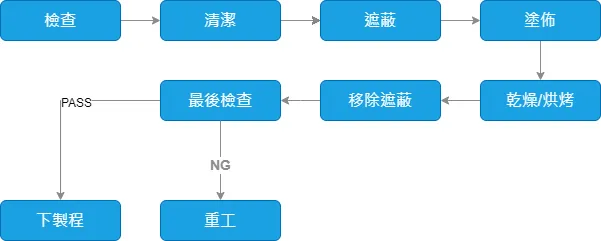

Conformal Coating Process

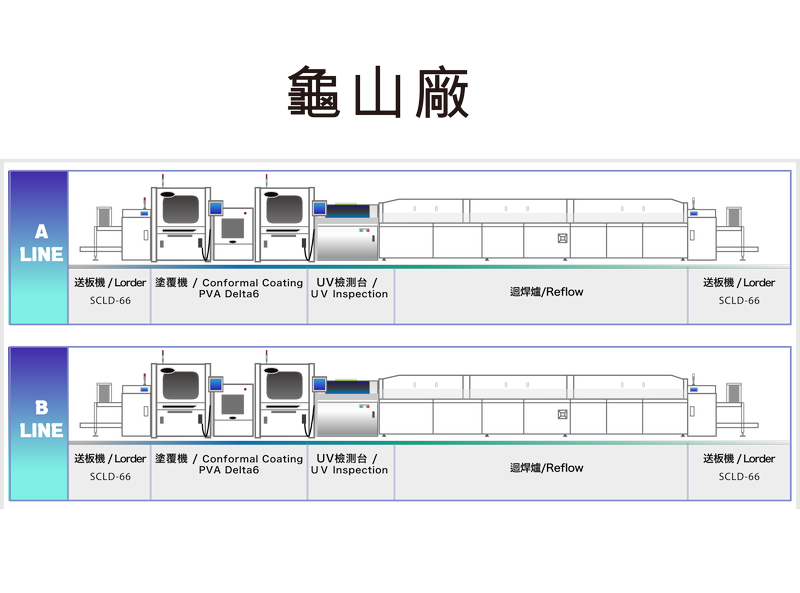

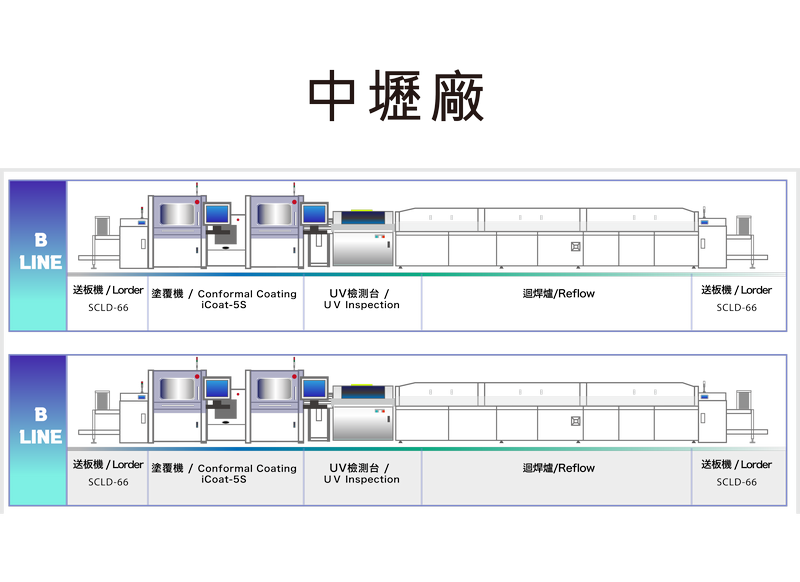

Coating Production Line

Conformal Coating Equipment Description

Delta 6

The exclusive patented five-axis (X, Y, Z, Tilt, 360° Rotate) control system is convenient and has no dead corners for coating and dispensing; the exclusive patented atomization valve and various valve head options can be used with complex The coating process can be combined at will; exclusive automatic valve head replacement system (fully automatic replacement); the valve is easy to maintain and has the longest service life (maintenance is completed in 10~15 minutes, no need to soak); the unique purge cup design makes valves and pipelines not easy to replace Hardening causes clogging; the software program is easy to program; the software can be used with the Barcode system & Shop Flow system; the entire machine is made in the United States and has high assembly quality;

- Complexity accuracy:+/-0.025mm

- Resolution:0.005mm

- Working size:537x485x100mm

- Loading capacity:11.4 kg

- Running movement speed:up to 500mm/sec

- Maximum product height:DELTA 6: 50mm / DELTA 8: 100mm

- Air pressure:80psi (5.5bar)

iCoat-5

Multi-directional and multi-angle spraying technology solves the problem of spraying parts in dead corners; high speed

- Complexity accuracy:+/-0.025mm

- Resolution:0.005mm

- Working size:900x485x100mm

- Loading capacity:11.4 kg

- Running movement speed:up to 500mm/sec

- Maximum product height:DELTA 6: 50mm / DELTA 8: 100mm

- Air pressure:80psi (5.5bar)

How Conformal Coating works

- 1. Use an automated spraying system to spray paint onto specific areas on the PCB circuit board.

- 2. Send the PCB circuit board to the oven for air drying and curing to avoid excessive coating thickness errors or airborne particles adhering to the wet coating surface.

- 3. Check the luminous paint through long-wave ultraviolet light.

- 4. Check whether the coating thickness meets quality specifications to ensure that the product can maintain long-term reliability after assembly.

- 5. Complete product production.